ScaleBuster is a Physical Water Conditioning technology, based on Electro-Static principles. With ScaleBuster installed, the hardness (typically Ca and Mg) is precipitated into suspension in a non-adherent crystalline structure contrary to the untreated hardness which tends to adhere to surfaces (which is known as “scaling”).

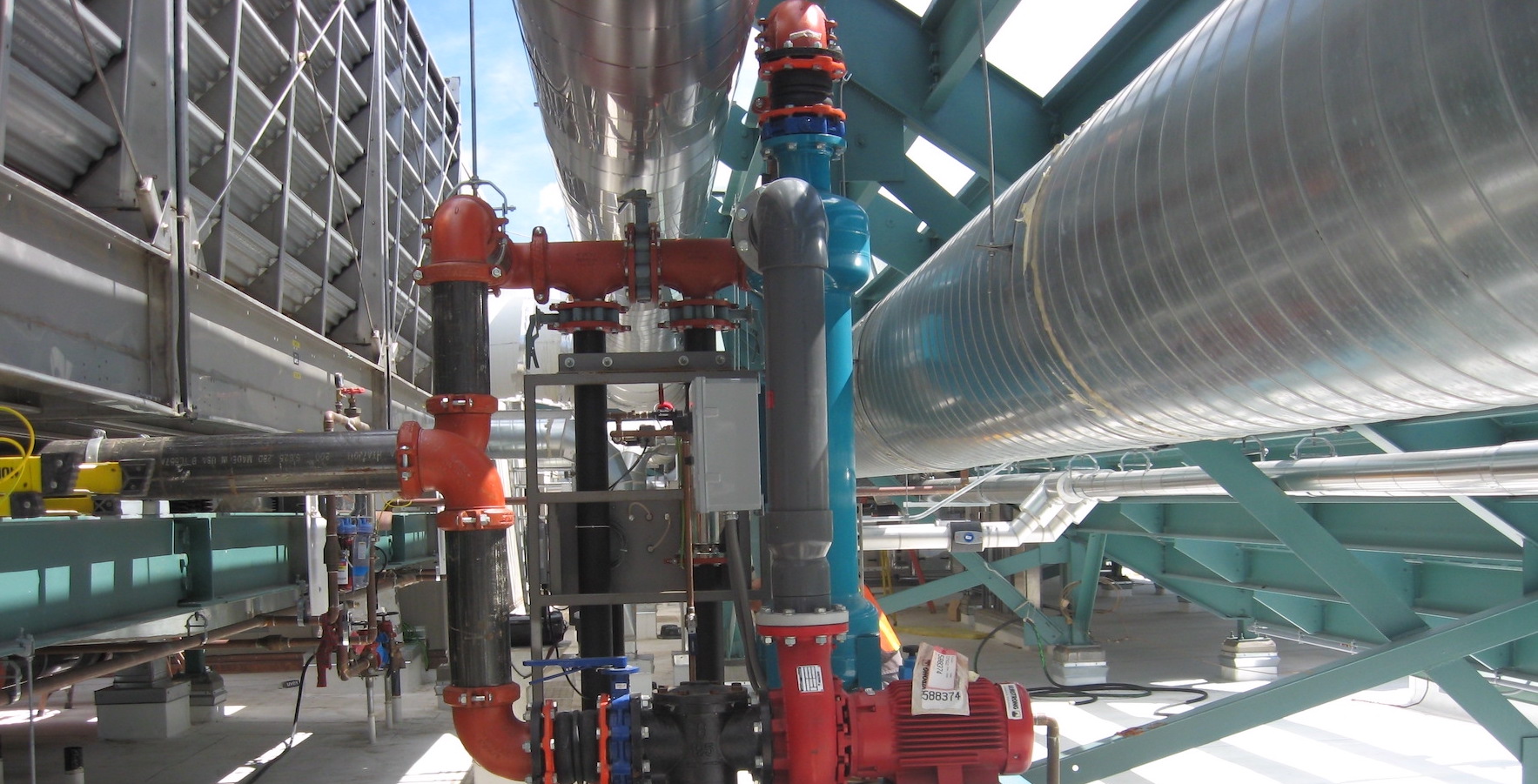

ScaleBuster-based EnviroTower® technology treats cooling tower systems and replaces traditionally chemical based or ion exchange softeners treatment with better results, allowing for 10-20% Operational Expenditures (OpEx) savings and longer equipment life (which falls under Capital Expenditure or CapEx, and can reach 10-15% of chiller cost!).

The EnviroTower solution typically saves water (10-40% depends on previous operation CoC), energy (10-15% on average), chemicals (over 90%) and labour (usually over 80%), improve corrosion situation in the cooling system (both in steel and in copper) and extends equipment life span by 10-15%! ROI is usually 2-3 years.

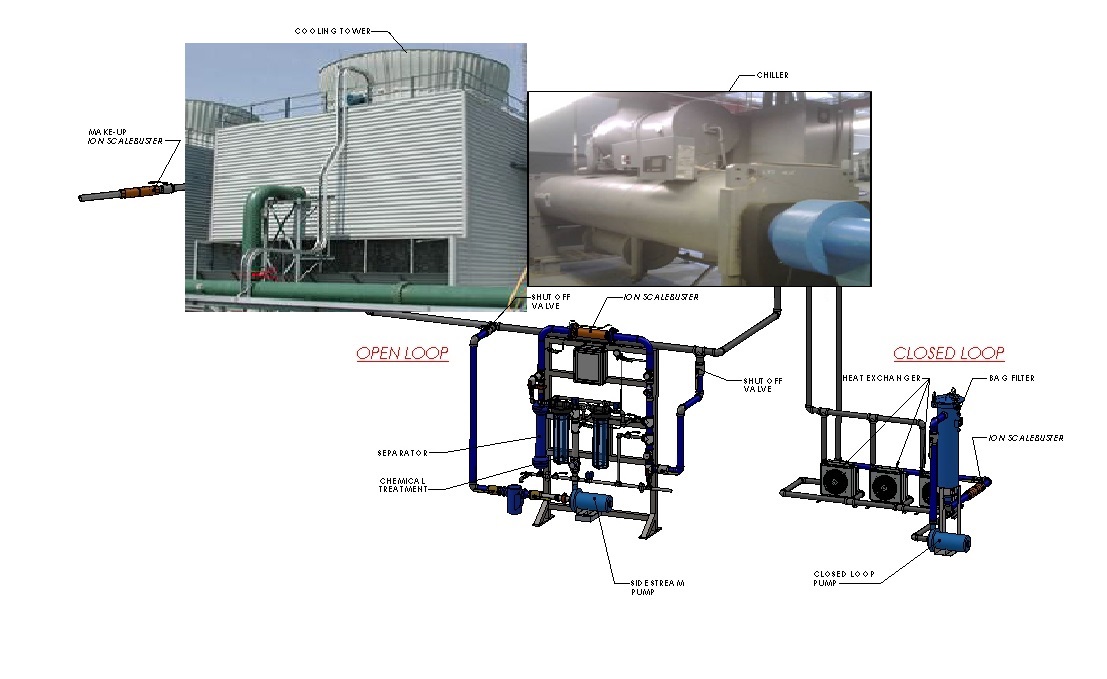

The HVAC (Heating, Ventilating, and Air Conditioning) cooling towers are used to dispose of unwanted heat from chillers (“reject” it). In areas with a hot climate, large hotels, office buildings, hospitals, airport terminals, shopping centers and schools typically use one or more cooling towers as part of their commercial air conditioning systems.

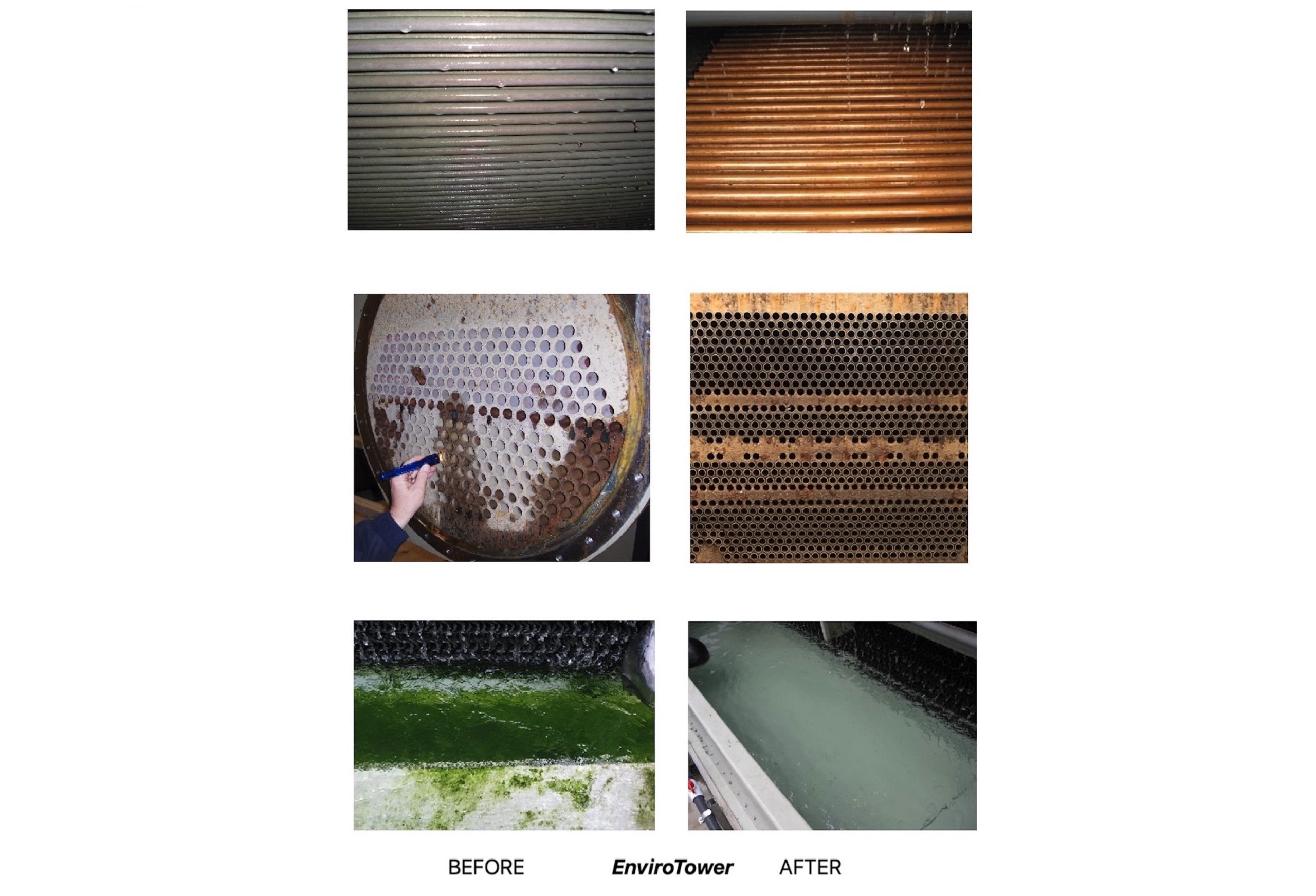

The water in the open circuit of the chiller-tower system must be properly treated to prevent scale, corrosion and biological material growth.

The patented EnviroTower – the Cooling Tower Water Treatment solution is designed around the ScaleBuster conditioner which precipitates the hardness (typically, Ca++ and Mg++ ions) in the cooling water, causing those ions to build clusters which grow larger as the water is recirculating through the ScaleBuster conditioner of the EnviroTower system, until they are removed from the water by a filtration or cyclonic separation process. The EnviroTower system is monitoring the cooling system’s water conductivity and controls the blowdown (allowing the operator to cycle up, saving water, while keeping the system scale-free). It also doses biocide as required, shocking the open circuit of the cooling tower once daily, as well as optional other chemicals (as Azole, to protect the copper tubes of the chillers). In a period of 30 minutes after dosing any chemical – the EnviroTower system avoids any blowdown (to eliminate drainage of the chemicals before they have actually performed in the water). The filtration or separation process removes the precipitated hardness with some water (as part of the blown down water). The EnviroTower controller is equipped with a light tower (green/amber/red) so the operator can simply and easily learn the status of the system. For more water conditioning, every make-up pipe is also equipped with a smaller ScaleBuster conditioner treating the water incoming into the cooling tower.

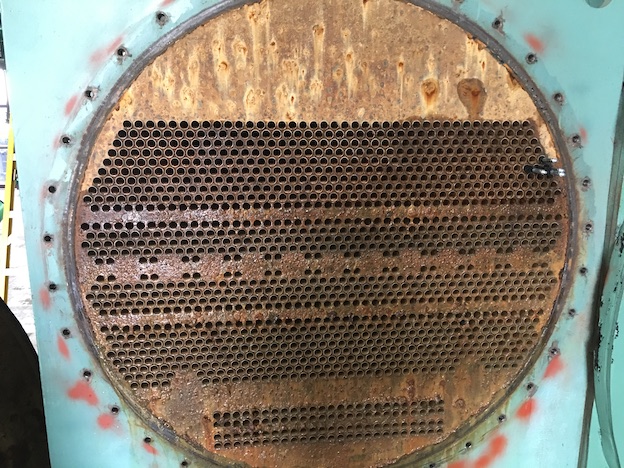

To summarize – EnviroTower replaces the traditional chemical treatment of the cooling water, eliminating the need for “chiller punching” which is mechanically cleaning the chiller tubes annually which involves a cost, of course, but also downtime, health & safety concern (as acid is used) as well as reducing the equipment’s life-expectancy, as this harsh cleaning process actually scraps the copper chiller tubes; saves water (as the cooling system can be cycled up for better efficiency) while saving energy (0.635mm – or 0.025” – of scale in the HVAC chillers would cost about 25% extra energy, and this is expensive!), labour and of course, chemicals (we need to remember that the chemical suppliers do want to sell more chemicals, in many cases we see that the system is very inefficient but still pumping a lot more than needed chemicals…).

We’ve listed some points below (which usually come up when we meet customers).

It is also important to mention that all our employees are salary-based (so no commission-motivated sales person will ever “push” a customer) for best customer service and integrity.

1) Who does EnviroTower compete with?

Chemicals (mostly, as said above): EnviroTower offers a number of benefits over incumbent chemical water treatment providers serving the cooling tower market:

- Performance: Chemicals application is very difficult and time consuming to deliver consistently. Inconsistent water treatment leads to scale, fouling and corrosion. The chemical suppliers admit that they can only provide about 90 percent protection against scale and biofilms[1]. This level of protection would lead to a 25 percent increase in energy costs in a typical system in several months.

- Economics: Based on energy, water, labour and chemical savings, EnviroTower is orders of magnitude more economical than chemical treatment. Also, as the chillers are kept scale-free there is no need to clean them periodically – saving the immediate cleaning costs and downtime, but also extending the life span of the chillers (as the aggressive scale cleaning shorten life expectancy of the chillers as to reduction of copper tubes wall thickness!).

- Environmental impact: EnviroTower’s approach ensures water being discharged from the system meets most potable drinking water standards (even in California, blowdown from towers equipped with EnviroTower systems are allowed either for irrigation or into the storm system!).

- Health & safety: There is no handling of harsh and hazardous chemicals with the EnviroTower

[1] Ashland Specialty Chemical web site (http://www.ashchem.com/ascc/drewind/performax.asp)

Other Physical Water Treatment solutions:

While there are numerous physical water treatment technologies available, all direct competitors are small, niche vendors with limited market traction. EnviroTower has distinct technical advantages over direct PWC competitors and in a side-by-side comparison of PWC technologies, its electrostatic technology is the clear leader.

How does EnviroTower differentiate from Incumbents?

- Complete solution: EnviroTower is a complete solution, not just a PWC for descaling. Customers understand that EnviroTower’s competitors cannot provide maximum biological protection and corrosion control with only a PWC device. The competition does not control blowdown, EnviroTower controls the blowdown by measuring the water conductivity in real-time, doses the required chemicals when needed and also removes precipitated hardness from the water (allowing for higher Cycles of Concentration for water saving). The Zinc anodes in the ScaleBuster conditioner give effective corrosion protection (passive cathodic protection).

- Superior core technology: EnviroTower’s core PWC technology ION ScaleBuster® is superior in its operation and performance. Its operation requires no chemicals, no electricity and there are no moving parts, so the device requires no maintenance. The ScaleBuster water conditioner consistently precipitates larger sized calcium carbonate particles than any competitive devices, which maximizes the performance and effectiveness of the device. As we also manufacture the ScaleBuster (in our UK facility) we are in full control of the technology.

2) Why are chemicals not effective in treating water in cooling towers?

Organizations that operate one or multiple cooling towers typically have inconsistent control of the key cooling tower problems – scale, fouling, corrosion and microbiological contamination.

Ideal water treatment requires the ability to constantly adjust to different water and tower conditions. With the varying water and tower conditions, coupled with fewer and fewer chemicals available to combat these problems, chemical treatment is a constant struggle.

The real evidence that there is room for improvement in chemical treatment, is the fact that virtually every cooling tower owner/operator pays for chemical treatment, and then pays a contractor to open up their chiller at the end of the season to try to get rid of that last little bit of scale and fouling in the chiller’s tube.

3) Why are companies switching to physical water conditioning?

The economic benefits of physical water conditioning are compelling – in North America, operating cost savings typically amount to 14 cents (US) per square foot per year. In EU, HK or Singapore the costs are slightly higher, in Macau and China about 11.5 cents (US).

Equally compelling are the ancillary benefits not included in the cost analysis – energy saving, water conservation, elimination of toxic water discharge to the municipal water system, and reduced maintenance overhead.

4) We hear often: I’ve heard physical water conditioning is questionable technology – why is your system any different?

Physical water conditioning (PWC) technology has a long history, much of it negative due to flawed design or improper application. Physical water conditioners can be grouped into generations:

| 1st Generation |

Magnetic, Electrolytic, Electronic |

| 2nd Generation |

Electromagnetic, Pulsed-power |

| 3rd Generation |

Cavitation |

| 4th Generation |

Electrostatic (with cavitation effects in the PWC process) |

It is widely accepted that the first generation of technologies have fundamental design issues and cannot possibly perform consistently or reliably. None of the organizations marketing these types of PWCs have had success. Electromagnetic and cavitation device types have had recent commercial success, however, each has a major technical fault.

Most PWC based solutions have focused on the removal of scale using physical water conditioners, but this approach is not a complete solution, as cooling water must still be controlled for factors other than just scale, including fouling and corrosion. For a cooling water treatment solution to be truly effective, it must control all these factors on a continuous basis and adjust to the constantly changing conditions in the cooling system environment. A trouble-free PWC will be self-cleaning, have no moving parts, and require no electricity.

New technologies such as EnviroTower has proven to be more effective and consistent in addressing all of the key problems with cooling tower water treatment, and a more cost-effective solution from a lifecycle and maintenance perspective.

Some facts about us: Environmental issues are adding extra costs in many industries, profits are down and bottom line numbers are affected. This situation is forcing industries to change their habits. Sustainable technologies, such as ScaleBuster®, are seeing increased investment from Global, European, North American and Far East Companies as business culture adapts. The ScaleBuster technology was developed and manufactured in United Kingdom has had more than US$8.5mn invested for its launch into the cooling system applications with our patented EnviroTower solution.

ION Enterprises has been trading since 1990, manufactures a range of environmental physical water treatment devices under the trademark ScaleBuster®. Over the years this technology has been installed by many well-known companies with excellent results. Our products have been applied into more than 300,000 applications to date, including over 480 EnviroTower systems. The company has 2 facilities in United Kingdom and Canada.

You are a very important customer for us, and we’d like to work further with you to answer all your questions and offer you the best solution for your HVAC system requirements, to allow you to save on your day-to-day operation.